Light Weight Aluminum Castings Explained: Trick Conveniences and Providers for Your Manufacturing Demands

Aluminum spreadings play a considerable duty in modern-day production. Their sturdy and light-weight nature makes them appropriate for various applications. Industries such as automotive and aerospace take advantage of their convenience. Recognizing the benefits and the manufacturing procedure of aluminum castings is necessary. Additionally, choosing the appropriate provider can affect high quality and efficiency. What factors should be taken into consideration when selecting a light weight aluminum casting service? Checking out these aspects reveals important understandings.

Benefits of Aluminum Castings

Aluminum castings offer various benefits that make them a favored option in various industries. Among the key advantages is their light-weight nature, which substantially decreases delivery and dealing with expenses. Furthermore, aluminum shows exceptional corrosion resistance, ensuring durability and minimized maintenance for items made from this material. The versatility of light weight aluminum allows for intricate layouts and complex forms, giving manufacturers with higher flexibility in production.

In enhancement, aluminum spreadings possess great thermal and electrical conductivity, making them appropriate for a selection of applications calling for heat dissipation or electrical parts. The material also has a high strength-to-weight ratio, making it possible for the manufacturing of sturdy yet lightweight elements. Furthermore, aluminum can be reused without losing its residential or commercial properties, advertising sustainability in making processes. Generally, these advantages make light weight aluminum castings a reliable and efficient alternative for producers seeking high quality and efficiency in their items.

Applications of Light Weight Aluminum Castings in Different Industries

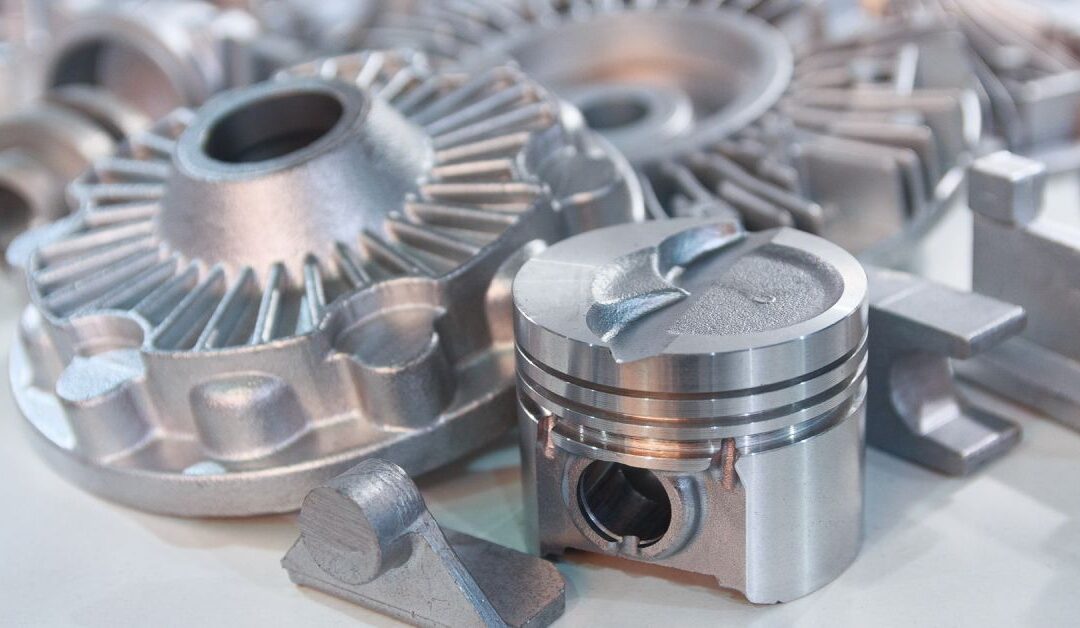

The benefits of aluminum castings make them extremely looked for after throughout various markets, consisting of vehicle, aerospace, and consumer items. In the automotive sector, they are made use of for engine blocks, transmission instances, and wheels due to their light-weight nature, which improves gas effectiveness. Aerospace applications benefit from light weight aluminum castings in architectural elements and real estates, providing strength while reducing weight, crucial for flight performance.

In durable goods, light weight aluminum spreadings are utilized in products such as kitchenware and electronic units, offering resilience and visual charm (Wisconsin Aluminum Foundry). Furthermore, the electrical industry utilizes light weight aluminum spreadings for warm sinks and housings, making sure efficient thermal management. The versatility of aluminum permits complicated geometries and complex designs, further expanding its applications. Generally, the diverse energy of light weight aluminum castings highlights their value in modern manufacturing, adding to technology and efficiency throughout these vital industries

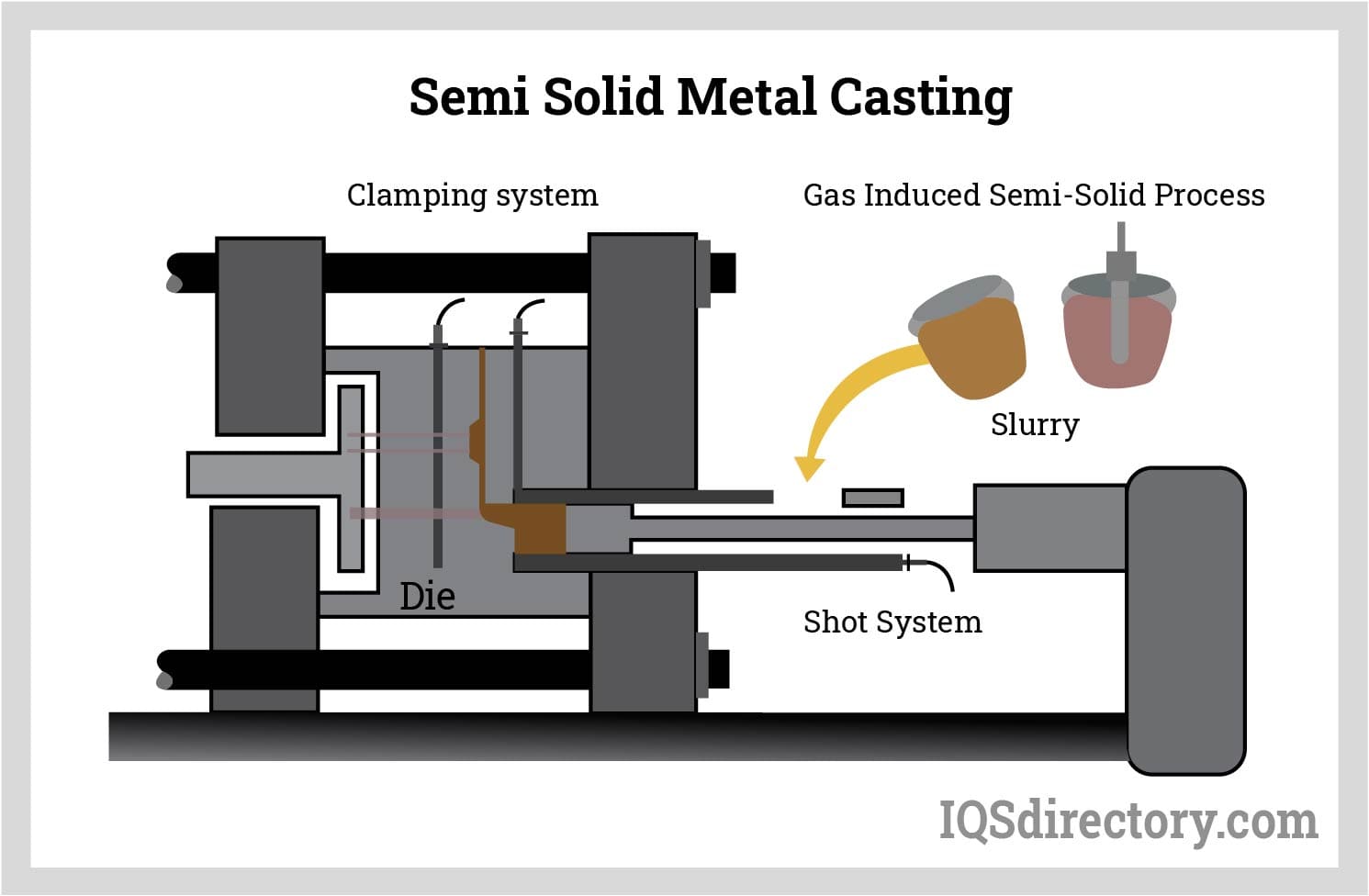

The Manufacturing Process of Aluminum Castings

Casting aluminum entails numerous vital steps that change raw steel into precise components. The procedure begins with the melting of aluminum scrap or ingots in a heating system, getting to temperature levels around 1,200 ° F. Once molten, the aluminum is put right into a mold and mildew, which can be made from sand, metal, or ceramic, relying on the wanted specifications.

After pouring, the steel cools and solidifies, creating the shape of the mold and mildew (Aluminum Foundry). The next action involves eliminating the casting from the mold, which may call for extra methods to guarantee a smooth surface finish

Ultimately, any type of excess material or imperfections can be machined or ground off to accomplish Aluminum Foundry the last dimensions. Quality evaluations are after that carried out to verify that the spreading fulfills required criteria. This thorough process enables suppliers to create elements that are light-weight, sturdy, and appropriate for a variety of applications.

Picking the Right Aluminum Spreading Service

When selecting an aluminum spreading solution, it is vital to contemplate numerous aspects that can substantially affect the top quality and efficiency of the last item. Initially, the provider's experience and competence in aluminum spreading play a vital duty in ensuring high-quality outcomes. Companies need to assess the company's portfolio and previous jobs to evaluate their capacities.

Additionally, assessing the technology and equipment utilized by the spreading solution is important, as modern-day machinery can enhance precision and lower preparations. One more crucial aspect is the ability to use customized remedies tailored to details project requirements, which can considerably boost item efficiency.

Interaction and consumer assistance should not be neglected; a joint companion can facilitate smoother job execution. Considering cost-effectiveness without endangering high quality is vital for making an informed choice. By very carefully evaluating these elements, suppliers can pick a spreading service that finest satisfies their needs.

Future Fads in Aluminum Casting Technology

As suppliers increasingly focus on high quality and effectiveness, developments in light weight aluminum spreading technology are established to transform the industry. Emerging fads consist additional reading of the fostering of automation and robotics, which enhance precision and reduce human mistake in casting procedures. Furthermore, the assimilation of expert system and equipment knowing is important source expected to enhance production schedules and enhance quality control.

Sustainability stays a main emphasis, with innovations in reusing strategies enabling more reliable reuse of light weight aluminum scrap, consequently reducing waste and power intake. Advanced simulation software is additionally obtaining grip, making it possible for engineers to design and predict casting efficiency before actual production, lessening costly mistakes.

Moreover, the growth of new alloys and advanced spreading approaches, such as 3D printing, will certainly increase the possibilities for light-weight yet durable components. With each other, these patterns suggest a dynamic future for light weight aluminum spreading, driven by technological developments that prioritize product, efficiency, and sustainability quality.

Frequently Asked Concerns

Just How Do Aluminum Castings Contrast to Other Materials?

What Are the Weight Limitations for Light Weight Aluminum Castings?

Weight constraints for aluminum spreadings usually depend on the style and application, however they usually sustain lots abilities ranging from a couple of ounces to numerous bunches. Specific restrictions emerge from elements like wall surface density and architectural honesty.

Can Light Weight Aluminum Castings Be Fixed After Production?

Light weight aluminum spreadings can be repaired after production, utilizing strategies such as welding or epoxy bonding. The feasibility of fixings depends on the degree of damages and the particular properties of the aluminum alloy made use of.

What Finishes Are Readily Available for Aluminum Castings?

Various coatings are offered for aluminum castings, consisting of anodizing, powder paint, covering, and polishing. These coatings improve look, provide corrosion resistance, and improve surface toughness, satisfying varied aesthetic and functional requirements in making applications.

Just How Do Ecological Rules Affect Light Weight Aluminum Spreading Processes?

Ecological guidelines considerably affect light weight aluminum casting procedures by mandating stricter discharges controls, motivating recycling techniques, and advertising sustainable materials. These laws urge makers to adopt cleaner innovations and reduce their environmental impact in manufacturing activities.